Shell's Z20LET Corsa C had been burning some oil and showing visible smoke, a common fault on the 2.0 Turbo Vauxhall engines. We had the car in a couple of weeks ago for diagnosis thinking that it was most likely going to be turbo oil drain related, as compression was good and we were under the predisposition that as the valve stem seals had been changed so recently that it wasn't going to be them. After removal of the turbo/manifold it was evident that the turbo was fine (fortunately) and that it was definitely the stem seals to blame, as the ports showed very bad fouling from burnt oil.

As can be seen all but one seal on the exhaust side had failed, it was highly probable that the inlet side was similar however that was not further looked into during this session as it was obvious the head needed rebuilding anyway.

A couple of weeks after the above we set about sorting it out with a full head off clean up.

|

| Syringe for removing pools of oil from the head bolts and other recesses |

|

| Magnet stick is the best and safest way to remove the tappets, |

|

| As suspected, more oil where you really don't want it |

Seeing that the inlet seals had failed as well confirmed our suspicions. Failure of every seal bar one is an improbable event, theoretically they all share a common mode of failure through wear of the material, obviously though these things are designed to last the life of the engine and as such its very unlikely that it is actually the part that has failed. All our fingers were pointing at bad installation, the 'garage' that had fitted these a few months before had done so with the head on method, which while in itself is a well established procedure when carried out properly (given appropriate engine condition), when combined with a lack of proper thought, execution, and pride in your work and reputation it leads to complete failure like this... rant over.

|

| Very fouled pistons |

|

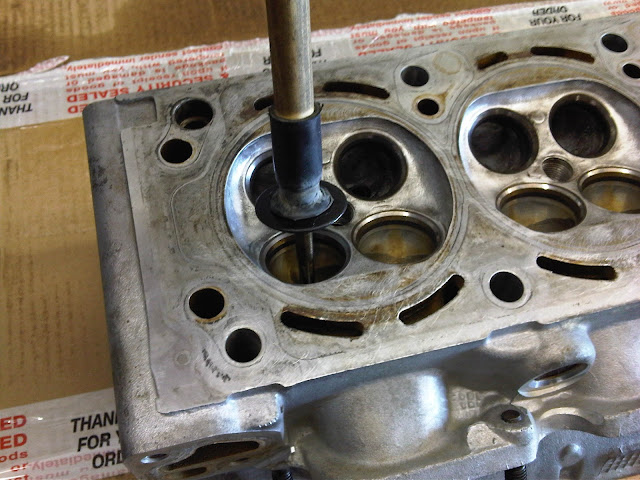

| Head on the bench |

With the head off we set about getting the valves out. I had bought another spring compressor for this job seeing as we were doing all 16 valves twice, my old one is from my dads days as an engineer and was a little out of shape. The new compressor I bought didn't have a standoff to suit engines with recessed valve springs (which is basically everything but 8 valvers with pressed steel cam covers) so one was knocked up

|

| Standoff tube faced square |

|

| Then welded on a nut to take a screw through the original compressor face |

|

| The stem seals all looked brand new (as they were!), but they were all sitting about half an inch off the guide! |

|

| Cleaning up the valves |

|

| Cleaning up the ports and head |

The pistons needed a bit of attention as well, as they had accumulated substantial deposits from all the oil that had been finding its way into the cylinders. The deposits on the pistons, head and valves combined added up to a significant proportion of TDC volume, with the effect of cranking up the static compression ratio which may explain a clockwork hesitation in the rev range as the engine came on boost, the ecu may have been detecting knock and attempting to compensate. Any comments on this from the automotive/motorsport people?

|

| Cleaning out the exhaust ports |

|

| Swapping the water pump was made more difficult by damaged bolts, eventually a nut ended up being welded on to get it out, access made it quite difficult |

|

| Water pump out |

|

| New stem seals installed and driven properly |

|

| Inlet cam (from another engine) retarded by a tooth |

|

| New exhaust studs |

|

| A fine specimen of an exhaust port |

|

| Turbo back on |

|

| Rad and intercooler back on |

After the mechanical work was done the next thing on the list was to wire in the push button start,

With all that done the car is now smoke free, the mid rev hesitation is gone, and the push button start is sweet.

Car is back to Weapon status.

Taa

No comments:

Post a Comment